- Aramid Fiber Interlaced Injection Molded Polypropylene (IMPP) cone construction

- Butyl rubber surround for strength and linearity during high excursion

Models

TS-D10LS4

10” Single 4Ω Voice Coil Subwoofer

- Shallow basket, small enclosure design for sound optimization and installation flexibility

| Sound Pressure Level (Sensitivity) | 76dB (± 1.5dB) |

|---|---|

| Frequency Range | 20 Hz to 3.4 kHz |

| Continuous Power Handling (RMS) | 350 Watts |

| Maximum Peak Power Handling | 1300 Watts |

| Nominal Impedance | 4Ω Single Voice Coil (SVC) |

| Diameter | 10” |

| Cone Material | Aramid Fiber Interlaced Injection Molded Polypropylene (IMPP) |

| Center Cap Material | Acrylonitrile Butadiene Styrene (ABS) |

|---|---|

| Surround Material | Butyl Rubber |

| Basket Material | Stamped Steel |

| Magnet Material | Ferrite |

| Magnet Weight | 43 oz |

| Mounting Depth | 3.3” |

TS-D10LS2

10” Single 2Ω Voice Coil Subwoofer

- Aramid Fiber Interlaced Injection Molded Polypropylene (IMPP) cone construction

- Butyl rubber surround for strength and linearity during high excursion

- Shallow basket, small enclosure design for sound optimization and installation flexibility

| Sound Pressure Level (Sensitivity) | 74dB (± 1.5dB) |

|---|---|

| Frequency Range | 20 Hz to 3.4 kHz |

| Continuous Power Handling (RMS) | 350 Watts |

| Maximum Peak Power Handling | 1300 Watts |

| Nominal Impedance | 2Ω Single Voice Coil (SVC) |

| Diameter | 10” |

| Cone Material | Aramid Fiber Interlaced Injection Molded Polypropylene (IMPP) |

| Center Cap Material | Acrylonitrile Butadiene Styrene (ABS) |

|---|---|

| Surround Material | Butyl Rubber |

| Basket Material | Stamped Steel |

| Magnet Material | Ferrite |

| Magnet Weight | 43 oz |

| Mounting Depth | 3.3” |

TS-D12D4

12” Dual 4Ω Voice Coil Subwoofer

- Aramid Fiber Interlaced Injection Molded Polypropylene (IMPP) cone construction

- Butyl rubber surround for strength and linearity during high excursion

- Oversized 74.1 oz double stacked magnet and vented pole yoke for increased power handling

| Sound Pressure Level (Sensitivity) | 78dB (± 1.5dB) |

|---|---|

| Frequency Range | 20 Hz to 4.7 kHz |

| Continuous Power Handling (RMS) | 600 Watts |

| Maximum Peak Power Handling | 2000 Watts |

| Nominal Impedance | 4Ω Dual Voice Coil (DVC) |

| Diameter | 12” |

| Cone Material | Aramid Fiber Interlaced Injection Molded Polypropylene (IMPP) |

| Center Cap Material | Acrylonitrile Butadiene Styrene (ABS) |

|---|---|

| Surround Material | Butyl Rubber |

| Basket Material | Stamped Steel |

| Magnet Material | Ferrite |

| Magnet Weight | 74.1 oz |

| Mounting Depth | 6.2” |

TS-D12D2

12” Dual 2Ω Voice Coil Subwoofer

- Aramid Fiber Interlaced Injection Molded Polypropylene (IMPP) cone construction

- Butyl rubber surround for strength and linearity during high excursion

- Oversized 74.1 oz double stacked magnet and vented pole yoke for increased power handling

| Sound Pressure Level (Sensitivity) | 76dB (± 1.5dB) |

|---|---|

| Frequency Range | 20 Hz to 4.7 kHz |

| Continuous Power Handling (RMS) | 600 Watts |

| Maximum Peak Power Handling | 2000 Watts |

| Nominal Impedance | 2Ω Dual Voice Coil (DVC) |

| Diameter | 12” |

| Cone Material | Aramid Fiber Interlaced Injection Molded Polypropylene (IMPP) |

| Center Cap Material | Acrylonitrile Butadiene Styrene (ABS) |

|---|---|

| Surround Material | Butyl Rubber |

| Basket Material | Stamped Steel |

| Magnet Material | Ferrite |

| Magnet Weight | 74.1 oz |

| Mounting Depth | 6.2” |

TS-D10D4

10” Dual 4Ω Voice Coil Subwoofer

- Aramid Fiber Interlaced Injection Molded Polypropylene (IMPP) cone construction

- Butyl rubber surround for strength and linearity during high excursion

- Oversized 56.4 oz double stacked magnet and vented pole yoke for increased power handling

| Sound Pressure Level (Sensitivity) | 76dB (± 1.5dB) |

|---|---|

| Frequency Range | 20 Hz to 6.6 kHz |

| Continuous Power Handling (RMS) | 500 Watts |

| Maximum Peak Power Handling | 1500 Watts |

| Nominal Impedance | 4Ω Dual Voice Coil (DVC) |

| Diameter | 10” |

| Cone Material | Aramid Fiber Interlaced Injection Molded Polypropylene (IMPP) |

| Center Cap Material | Acrylonitrile Butadiene Styrene (ABS) |

|---|---|

| Surround Material | Butyl Rubber |

| Basket Material | Stamped Steel |

| Magnet Material | Ferrite |

| Magnet Weight | 56.4 oz |

| Mounting Depth | 5.5” |

TS-D10D2

10” Dual 2Ω Voice Coil Subwoofer

- Aramid Fiber Interlaced Injection Molded Polypropylene (IMPP) cone construction

- Butyl rubber surround for strength and linearity during high excursion

- Oversized 56.4 oz double stacked magnet and vented pole yoke for increased power handling

| Sound Pressure Level (Sensitivity) | 74dB (± 1.5dB) |

|---|---|

| Frequency Range | 20 Hz to 6.6 kHz |

| Continuous Power Handling (RMS) | 500 Watts |

| Maximum Peak Power Handling | 1500 Watts |

| Nominal Impedance | 2Ω Dual Voice Coil (DVC) |

| Diameter | 10” |

| Cone Material | Aramid Fiber Interlaced Injection Molded Polypropylene (IMPP) |

| Center Cap Material | Acrylonitrile Butadiene Styrene (ABS) |

|---|---|

| Surround Material | Butyl Rubber |

| Basket Material | Stamped Steel |

| Magnet Material | Ferrite |

| Magnet Weight | 56.4 oz |

| Mounting Depth | 5.5” |

Technology

Butyl Rubber Surround

Made of a specially blended, highly durable and moisture-resistant compound, butyl rubber keeps the cone moving in a linear direction, seals the cone to the basket and quickly dampens cone vibration once the signal has changed or stopped. This results in less distortion and superior frequency response.

Aramid Fiber Interlaced Injection Molded Polypropylene (IMPP)

Polypropylene (PP) is a tough thermoplastic resin that is an ideal material for a subwoofer cone – with low mass and high damping, PP cones offer good sensitivity and low distortion. However, polypropylene cones lack the rigidity and strength required for high output and extreme low bass. To resolve this, Pioneer engineers using advanced Computer-Aided Manufacturing, developed a process to blend aramid fibers into the polypropylene resin during the injection molding process. The resulting Aramid Fiber Interlaced IMPP subwoofer cone is incredibly strong and low mass with high rigidity and superior strength to produce deep, powerful and undistorted bass.

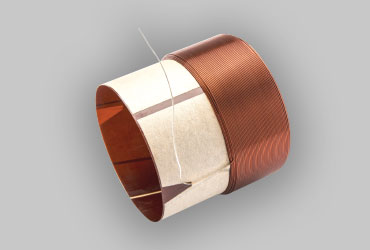

Large Diameter Voice Coil and Double Stacked Magnets

A subwoofer motor structure consists of the voice coil and magnet assembly. Increasing the diameter and length of the voice coil provides greater control of the woofer cone and higher power handling. However, to take full advantage the magnet must also be increased, both in magnetic power and physical size. The D subwoofer uses an oversized 4-layer voice coil and high energy double stacked magnets to increase the overall power handling and SPL output with no sacrifice in sound quality.

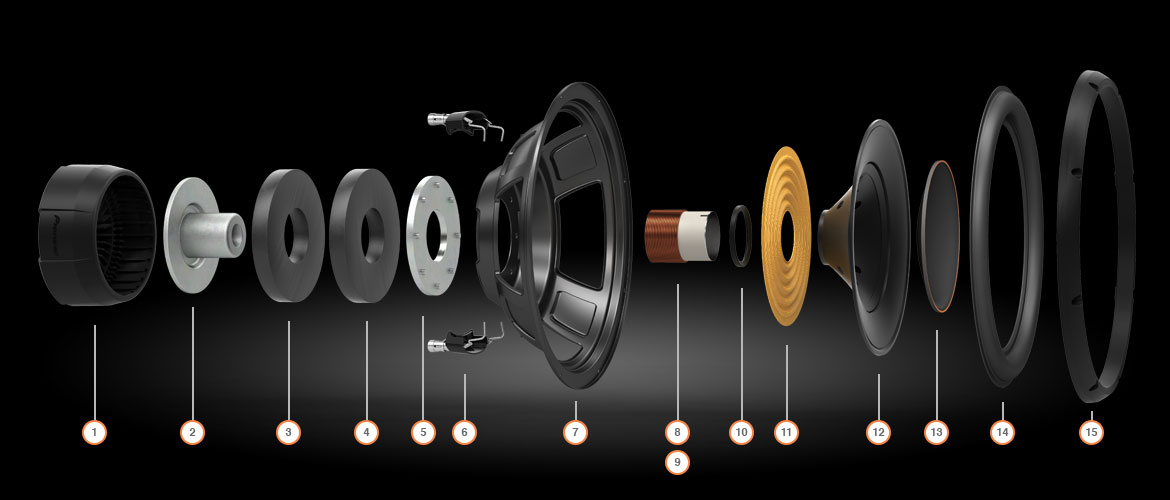

TS-D12D4 12” Dual 4Ω Voice Coil Subwoofer

1 Magnet Boot

2 Yoke

3 37 oz Lower Stacked Magnet

4 37 oz Upper Stacked Magnet

5 Top Plate

6 Input Terminals

7 Stamped Steel Basket

8 4-layer Copper Voice Coil Wire

9 Aluminum Voice Coil Former

10 Spider Neck Holder

11 Meta-aramid Fiber Spider

12 Aramid Fiber Interlaced IMPP Cone

13 ABS Center Cap

14 Butyl Rubber Surround

15 Gasket

Specifications

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|

| TS-D10LS4 | TS-D10LS2 | TS-D12D4 | TS-D12D2 | TS-D10D4 | TS-D10D2 | |

| Subwoofer | ||||||

| Sound Pressure Level (Sensitivity) | 76dB (± 1.5dB) | 74dB (± 1.5dB) | 78dB (± 1.5dB) | 76dB (± 1.5dB) | 76dB (± 1.5dB) | 74dB (± 1.5dB) |

| Frequency Range | 20 Hz to 3.4 kHz |

20 Hz to 3.4 kHz |

20 Hz to 4.7 kHz |

20 Hz to 4.7 kHz |

20 Hz to 6.6 kHz |

20 Hz to 6.6 kHz |

| Continuous Power Handling (RMS) | 350 Watts | 350 Watts | 600 Watts | 600 Watts | 500 Watts | 500 Watts |

| Maximum Peak Power Handling | 1300 Watts | 1300 Watts | 2000 Watts | 2000 Watts | 1500 Watts | 1500 Watts |

| Nominal Impedance | 4Ω Single Voice Coil (SVC) | 2Ω Single Voice Coil (SVC) | 4Ω Dual Voice Coil (DVC) | 2Ω Dual Voice Coil (DVC) | 4Ω Dual Voice Coil (DVC) | 2Ω Dual Voice Coil (DVC) |

| Resonance Frequency (f0) | 37 Hz | 36 Hz | 34 Hz | 33 Hz | 41 Hz | 40 Hz |

| DC Resistance | 3.3Ω x2 | 1.7Ω x2 | 3.3Ω x2 | 1.7Ω x2 | 3.6Ω x2 | 1.7Ω x2 |

| Diameter | 10” | 10” | 12” | 12” | 10” | 10” |

| Cone Material | Aramid Fiber Interlaced IMPP | Aramid Fiber Interlaced IMPP | Aramid Fiber Interlaced IMPP | Aramid Fiber Interlaced IMPP | Aramid Fiber Interlaced IMPP | Aramid Fiber Interlaced IMPP |

| Drive Cone Material | - | - | - | - | - | - |

| Center Cap Material | Acrylonitrile Butadiene Styrene (ABS) | Acrylonitrile Butadiene Styrene (ABS) | Acrylonitrile Butadiene Styrene (ABS) | Acrylonitrile Butadiene Styrene (ABS) | Acrylonitrile Butadiene Styrene (ABS) | Acrylonitrile Butadiene Styrene (ABS) |

| Surround Material | Butyl Rubber | Butyl Rubber | Butyl Rubber | Butyl Rubber | Butyl Rubber | Butyl Rubber |

| Basket Material | Stamped Steel | Stamped Steel | Stamped Steel | Stamped Steel | Stamped Steel | Stamped Steel |

| Spider Material | Conex (double) | Conex (double) | Meta-aramid Fiber | Meta-aramid Fiber | Meta-aramid Fiber | Meta-aramid Fiber |

| Magnet Material | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite |

| Magnet Weight | 43 oz | 43 oz | 74.1 oz | 74.1 oz | 56.4 oz | 56.4 oz |

| Pole Size | 40mm | 40mm | 48mm | 48mm | 40mm | 40mm |

| Voice Coil Former Material | Glass imide | Glass imide | Aluminum | Aluminum | Aluminum | Aluminum |

| Voice Coil Wire Material | Copper, round wire | Copper, round wire | Copper, round wire | Copper, round wire | Copper, round wire | Copper, round wire |

| Voice Coil Layers | 4 | 4 | 4 | 4 | 4 | 4 |

| Mounting Depth | 3.3” | 3.3” | 6.2” | 6.2” | 5.5” | 5.5” |

| Screw Pitch Diameter (mm • inch) | Ø 252mm • 9-7/8” Dia. | Ø 252mm • 9-7/8” Dia. | Ø 301.4mm • 11-7/8” Dia. | Ø 301.4mm • 11-7/8” Dia. | Ø 251.8mm • 9-7/8” Dia. | Ø 251.8mm • 9-7/8” Dia. |

| Thiele / Small Parameters | ||||||

| Re (Ω) | 3.3 per vc | 1.7 per vc | 3.3 per vc | 1.7 per vc | 3.6 per vc | 1.7 per vc |

| Le (mH) | 2.09 | 1.35 | 4.52 (8Ω) 1.14 (2Ω) |

2.80 (4Ω) 0.72 (1Ω) |

4.31 (8Ω) 1.08 (2Ω) |

2.59 (4Ω) 0.66 (1Ω) |

| Fs (Hz) | 37 | 36 | 34 | 33 | 41 | 40 |

| Qms | 11.91 | 11.71 | 9.75 | 9.71 | 8.41 | 8.74 |

| Qes | 0.86 | 0.80 | 0.74 | 0.69 | 0.85 | 0.76 |

| Qts | 0.80 | 0.75 | 0.69 | 0.64 | 0.77 | 0.70 |

| Vas (liters • cu ft.) | 19.8 • 0.70 | 18.0 • 0.64 | 47.9 • 1.69 | 46.2 • 1.63 | 22.3 • 0.79 | 20.9 • 0.74 |

| Rms (kg/s) | 2.89 | 3.32 | 3.92 | 4.13 | 3.69 | 3.76 |

| Mms (g) | 148 | 171 | 183 | 193 | 124 | 131 |

| Cms (mm/N) | 1.2x10-4 | 1.1x10-4 | 0.13 | 0.12 | 0.14 | 0.12 |

| Diameter (mm • inch) | 207 • 8.1 | 207 • 8.1 | 256 • 10.1 | 256 • 10.1 | 209 • 8.2 | 209 • 8.2 |

| BL (T·m) | 12.3 | 9.8 | 19.2 (8Ω) 9.5 (2Ω) |

14.6 (4Ω) 7.3 (1Ω) |

16.1 (8Ω) 8.0 (2Ω) |

12.7 (4Ω) 6.4 (1Ω) |

| Xmax (mm • inch) | 8.3 • 0.32 | 7.9 • 0.31 | 13.0 • 0.51 | 13.0 • 0.51 | 10.8 • 0.42 | 9.8 • 0.38 |

| Sealed Enclosure Volume cu ft. (min • rec • max) | 0.35 • 0.6 • 0.7 | 0.35 • 0.6 • 0.7 | 0.8 • 1.0 • 1.2 | 0.8 • 1.0 • 1.2 | 0.5 • 0.7 • 0.8 | 0.5 • 0.7 • 0.8 |